Hannover Messe 2023

CELEST at Hannover Messe 2023

The Center for Electrochemical Energy Storage Ulm & Karlsruhe (CELEST) participates at the Hannover Messe from 17th to 21st April 2023 as co-exhibitor at the Baden-Württemberg Pavilion in the Energy Solutions Area in hall 12, booth D15.

At the booth we present new battery materials, different cell types including round and pouch cells from ZSW and KIT Battery Technology Center and a SCARA robot for stacking pouch cells including electrode magazine and gripper. Furthermore we inform about our platform and the various activities.

Cluster of Excellence POLiS - Batteries for a Sustainable Future

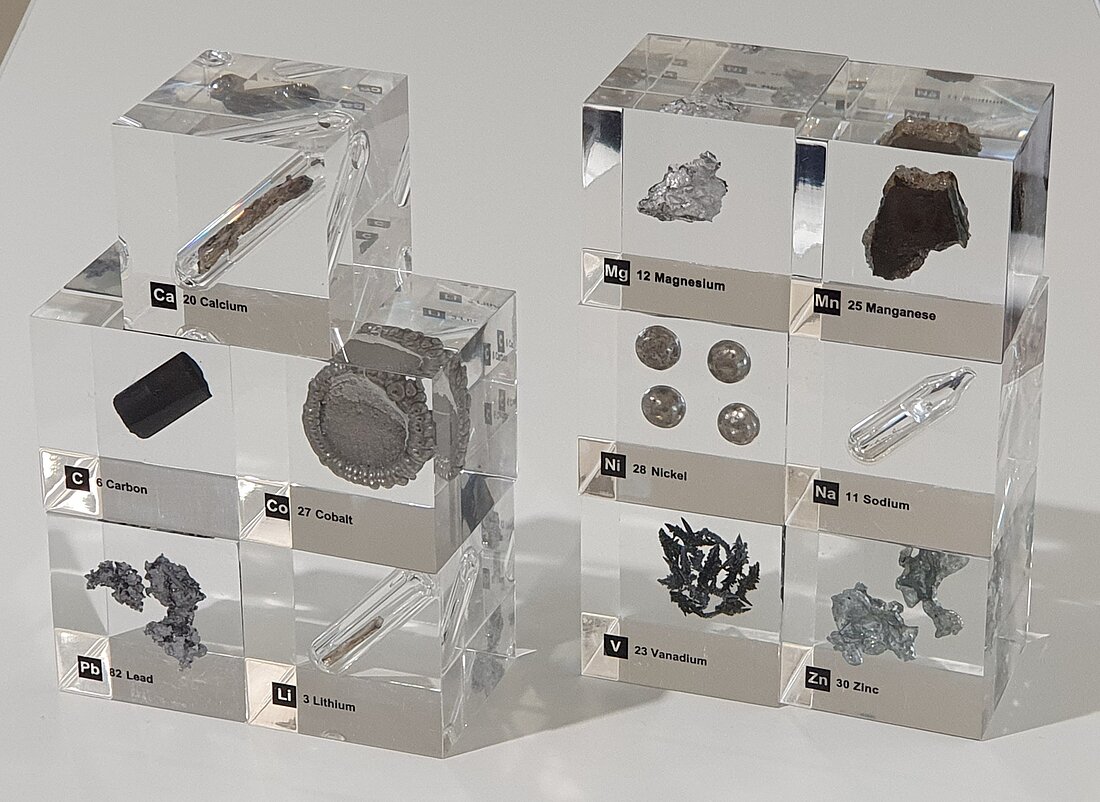

Batteries play a central role in the energy and transport revolution. In the Cluster of Excellence POLiS, batteries of the future are being researched, batteries that are more powerful, reliable, sustainable and environmentally friendly than current lithium-ion batteries.

The Cluster aims at developing electrode materials and electrolytes that allow for sustainable systems based on Sodium, Magnesium, Calcium, Aluminium, and Clorine ions.

Click here for more information on the research happening in the Cluster of Excellence POLiS.

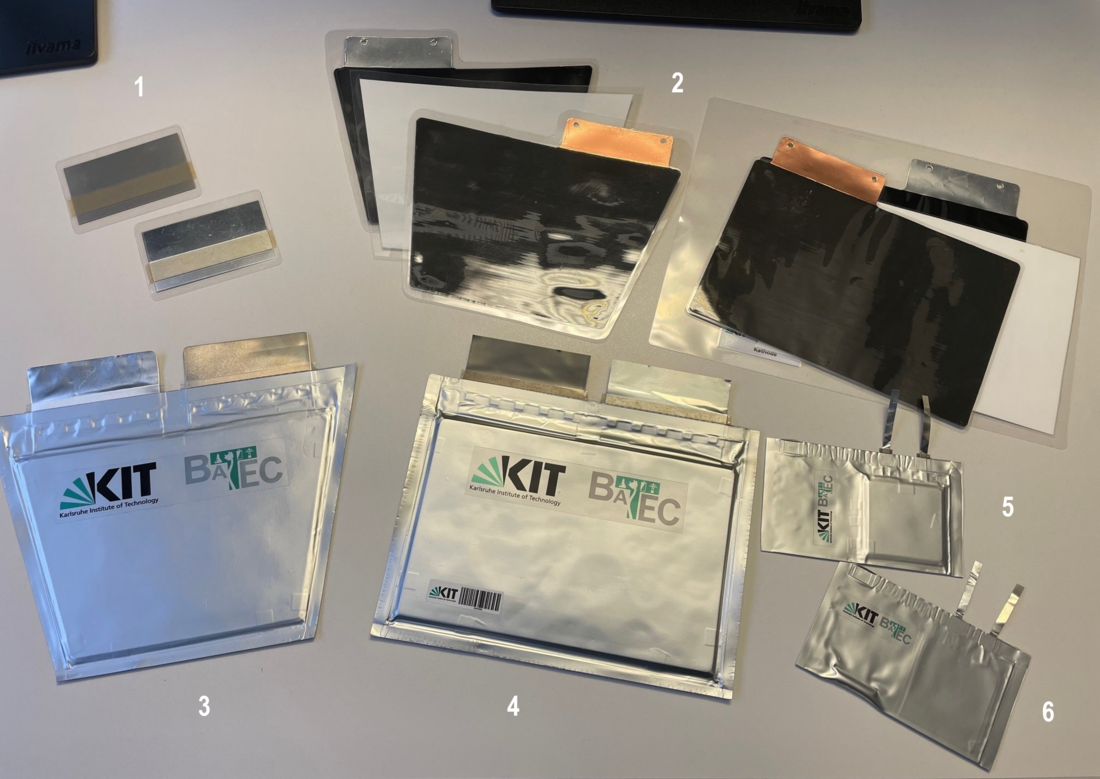

Cell Development and Testing at KIT Battery Technology Center

Generation, storage and use of electric energy on a sustainable and cost-efficient basis for stationary and mobile applications are among the biggest global challenges for the next decades. The research and development of innovative electrical energy storage systems is carried out in different institutes at KIT covering the entire value chain in a comprehensive, interdisciplinary approach. The objective is to develop industrially applicable, cost-efficient solutions for energy storage of the next generations.

The focus of cell development is on product-related research and development in lithium-ion cell technology with the objective to develop high quality and high performance cells. In cell testing, electrical cell characterization including long-term tests and application-oriented assessments can be carried out for the determination of cell performance.

For further information please visit:

Battery Technology Center: www.batterietechnikum.kit.edu

Work Group Cell Development: www.iam.kit.edu/ess

Bramsiepe / KIT

Bramsiepe / KIT

wbk - Institute of Production Science

On display is a low-pressure large-area gripper, as developed at the wbk - Institute of Production Science in the Smart Battery Maker project and currently being used in the AgiloBat research project, among others. The gripper connected to the SCARA robot is used to remove individual electrode sheets from the magazine on display and then build a cell stack from them. Separate grippers are used for anodes, cathodes and separators. The special shape of the grippers, together with the separately controllable suction surfaces, enable gentle and precise handling of the individual sheets without double-layered gripping of the sheets.

Further information can be found on the website of the wbk, as well as on the project website of AgiloBat.

ZSW

ZSW

Zentrum für Sonnenergie- und Wasserstoff-Forschung Baden-Württemberg (ZSW)

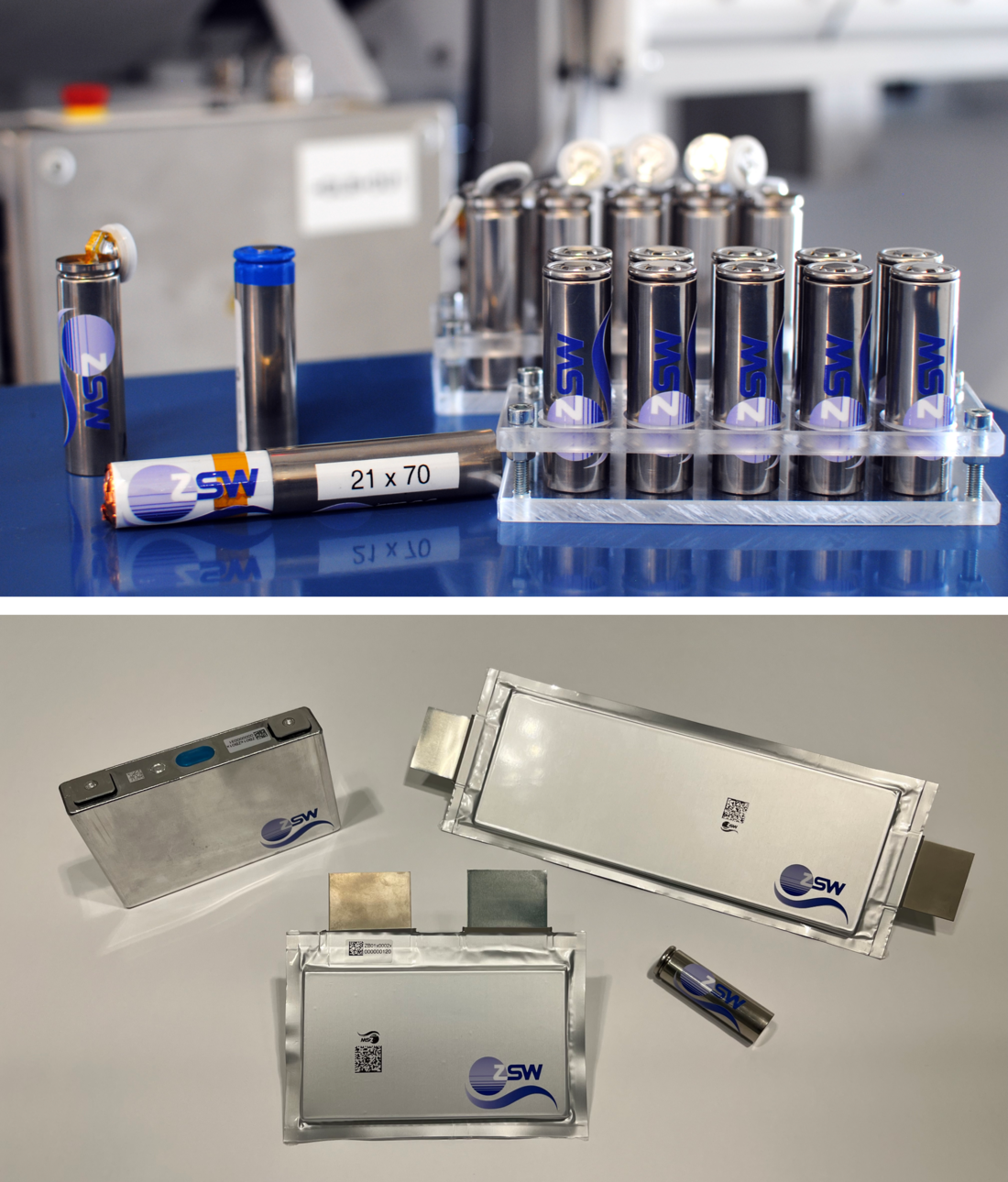

The Zentrum für Sonnenenergie-und Wasserstoff-Forschung Baden-Württemberg (ZSW) is one of the leading institutes for applied research in the areas of photovoltaics, battery technology, fuel cells, renewable fuels, and energy system analysis. The Ulm- site focuses on batteries and fuel cells development as well as Hydrogen technologies. The work covers the full value chain from materials to systems including testing and recycling. This also includes modelling and simulation of electrochemical processes, synthesis and characterization of innovative materials, components optimization and their pilot production. New products are qualified and tested as demonstrators in the field. Working very closely with industry, research institutes and universities, we take an application-minded approach to R&D.

A new generation of batteries is released every second years. This is only possible with a high speed in development, optimization and production transfer. On the other hand, such ongoing development ensures constant cost reduction in parallel to performance increase. In addition, topics such as availability of critical raw materials as well as reduction of ecological footprint had been gaining importance over the last years. It is therefore important for ZSW to stay close to industry and to work on the latest battery technology. ZSW therefore is constantly upgrading and expanding its facilities – especially for the assembly of pouch and PHEV2 cells of up to 80 ampere-hours and for 46800 round cells by the end of 2023.

Further information can be found here.