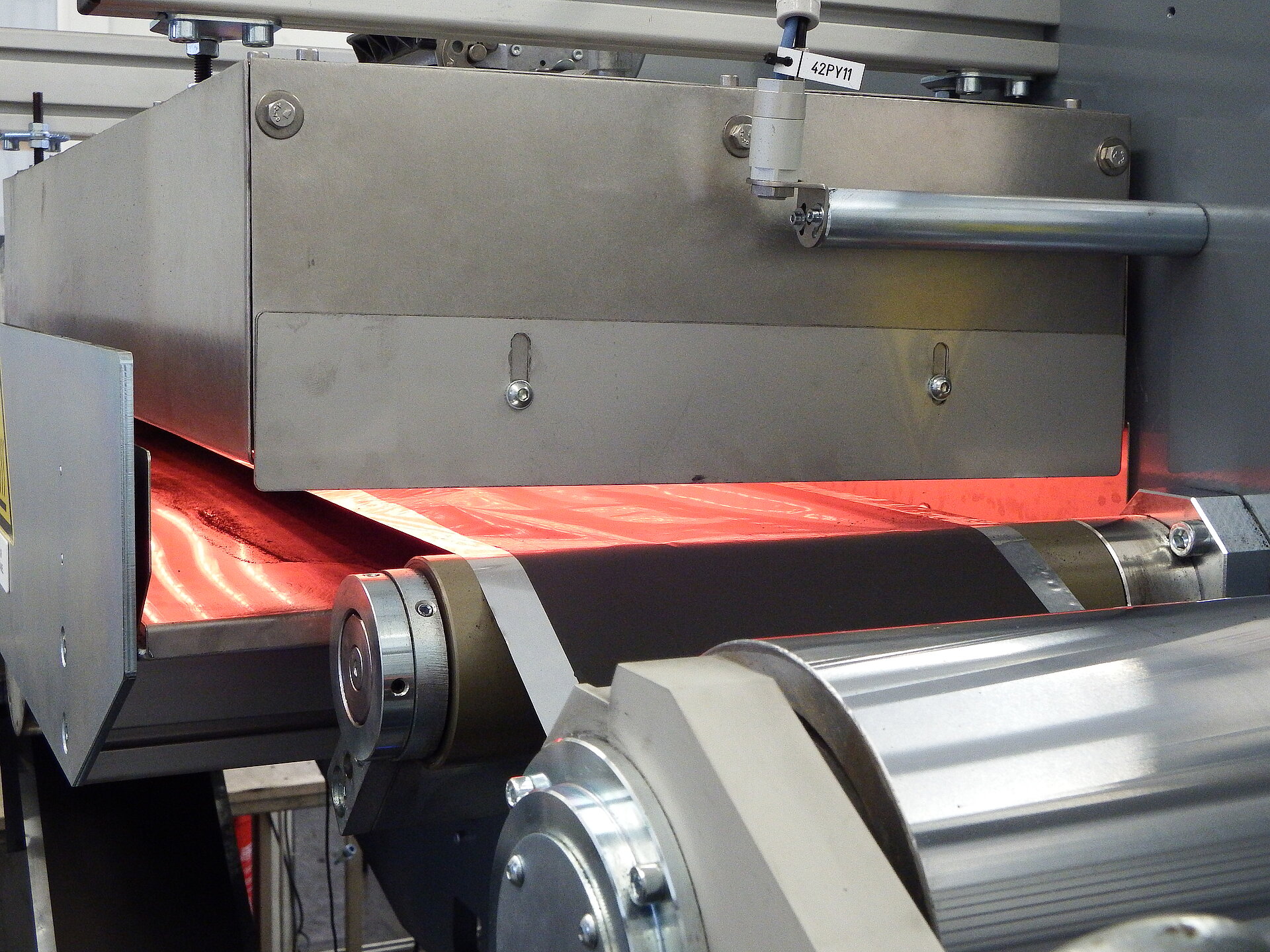

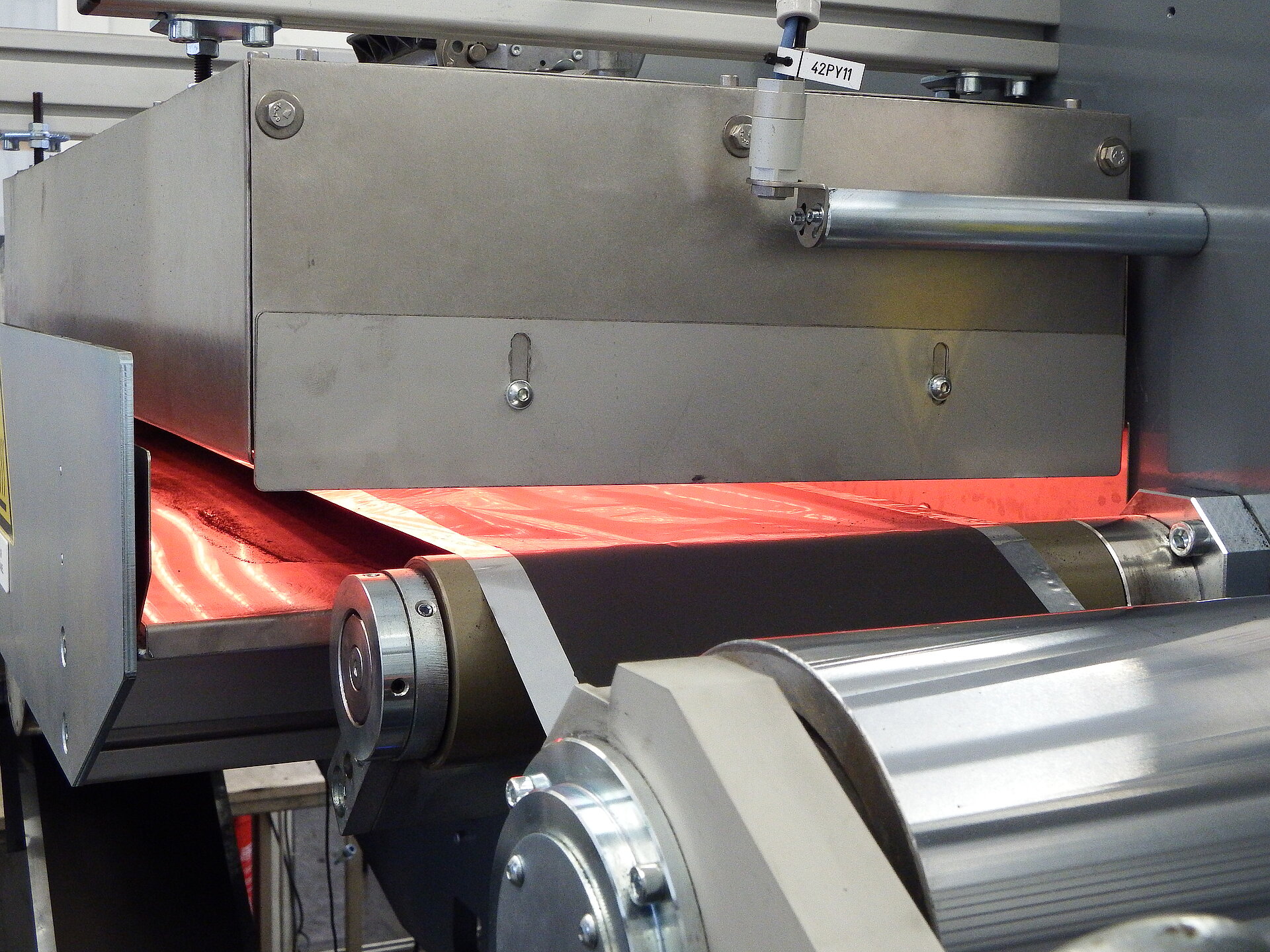

The production of e-car batteries is very energy-intensive, which is why the cars start with a negative CO2 balance - often referred to as a CO2 backpack. One process that could significantly improve this balance is the dry coating of electrodes in battery production. Normally, the electrodes are coated with a liquid paste, which is very time-consuming. Our expert, Inga Landwehr (Fraunhofer IPA), assumes that between 60 and 70% of the energy could be saved in the dry production of the electrodes. This would not only lead to a better CO2 balance, but would of course also reduce the cost of the cars.

VW and Tesla are the best-known car manufacturers that rely on dry coating. While Tesla apparently still has some difficulties with the cathode, VW says it has found a solution to use the process for its own cell production in Salzgitter.